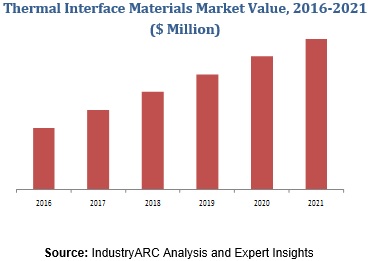

The report provides detailed report of the types and applications of Thermal interface materials (TIM) implemented in various end user industries all over the world. The Global Thermal Interface Materials market recorded annual revenue of $1407.13 million in 2017 and is estimated to grow at a CAGR of 7.4% during the forecast period 2018-2023. Gap filler is the major segment which holds almost 23.8% of the market share and is estimated to grow at a CAGR of 7.8% during the forecast period. Amongst all the applications, Telecommunications have the highest CAGR of 8.1% and is expected to grow rapidly till 2023. Usage of carbon nanotubes is a recent development in the field of thermal interface materials, they give better performance along with occupying relatively very less surface area. Asia-Pacific region has dominated the market with annual revenue of $830 million in 2017 and is estimated to grow at a CAGR of 8.0% during the forecast period.

- The new class of Thermal Interface Materials delivers ultralow thermal resistance for compact power electronics. When electronics get more compact and robust, the heat dissipated per unit area of the electronic devices increases and moving components of machinery operate at higher speeds, creating additional heat. Thermal Interface Materials enable the removal of heat generated from the operation of electro-chemical, electronic and mechanical devices. These new TIMs fill the gaps between thermal transfer surfaces such as microprocessors and power electronics devices, and the heat sinks to increase thermal transfer efficiency.

- A new generation of polymer-based TIMs are introduced in the chemical industry, which uses boron nitride nanosheet (BNNS) fillers to enhance thermal conductivity. BNNS is a two-dimensional crystalline form of hexagonal boron nitride (h-BN), also known as white graphene. It has a similar geometry to all of its carbon analog graphene but few very different properties. A recent study demonstrates that an h-BN thin film composed layer-by-layer of laminated h-BN nanosheets can enhance lateral heat dissipation on a substrate. Thermal performance has improved with the boron nitride coating due to its anisotropic thermal conductivity.

- We also publish more than 100 reports every month in "Chemicals and Materials", Go through the Domain if there are any other areas for which you would like to get a market research study.

Comments

Post a Comment